Closure Systems

Efficient plastic series production for packaging solutions. Focus on tightness and flip-top functions.

- Material: PP / PE

- High-Volume Production

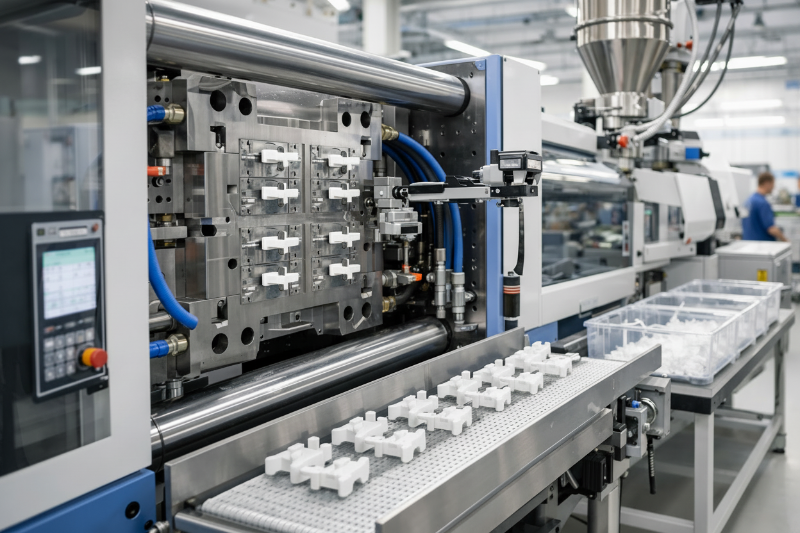

We don't just manufacture parts, we solve requirements. Here you can see examples of high-quality injection molded parts from packaging, industry, and assembly production. Our focus is on process-reliable plastic series production based on your CAD data for the DACH market.

In our plastic production, we cover a wide spectrum. We coordinate details such as material (thermoplastics), tolerances, and surface quality in injection molding technology individually to your needs.

Functional technical plastic parts, clips, and holders. Focus on dimensional accuracy and repeatability in the injection molding process.

Optical visible parts and functional plastic components with clean surfaces and clear details for the end market.

Customer-specific geometries and complex plastic engineering for snap-fits and integrated hinges.

Visualization of typical requirements from our plastic processing.

Efficient plastic series production for packaging solutions. Focus on tightness and flip-top functions.

Precision injection molding technology for electronic components with rib structures and warpage-free quality.

Mechanically resilient injection molded parts such as clips and holders. Designed for high tensile strength.

Flawless surfaces in the injection molding process. Ideal for end-customer products with EDM texture.

Complete system solutions from our plastic production. We assemble seals and sets.

From idea to series production. We manufacture prototype tools and small series for product development, market tests, and pre-series sampling.

SVAROX in Kruševac, Serbia, is your reliable production partner for plastic injection molding with delivery to Germany, Austria, and Switzerland. As an alternative to production in Asia, we offer you shorter delivery routes, European quality standards, and personal service in German language.

In the field of injection molded parts nearshoring Serbia, you benefit at SVAROX from legal security and cultural proximity. Our production facility combines modern injection molding technology with efficient manufacturing costs.

Send us your CAD data (STEP/IGES). We check feasibility and material usage in the injection molding process and provide you with a quote at short notice for your series production.

Request QuoteWe are flexible and can economically produce both small series from 500 pieces as well as large series with several hundred thousand parts.

From inquiry to first sample delivery typically takes 8-12 weeks, depending on the complexity of the mold.

We deliver via freight carrier directly to you. Transit time from Serbia to Germany is typically 2-3 business days. Upon request, we also handle complete customs clearance.

We work according to European quality standards with documented process control. Upon request, we provide measurement protocols, material certificates, and initial sample inspection reports (ISIR).

We process all common thermoplastics such as PP, PE, ABS, PC, PA6, PA6 GF, POM, and TPE. For special material requirements, we are happy to advise you.

Yes, we also take over production with your existing mold. We check the condition, perform maintenance if necessary, and start series production.

Our team speaks fluent German. You have a direct contact person for all technical and commercial questions – without language barriers.

We work with all common formats: STEP, IGES, Parasolid, SolidWorks, and CATIA. Simply send us your 3D data and we will check feasibility.