Closure & Dosing Systems

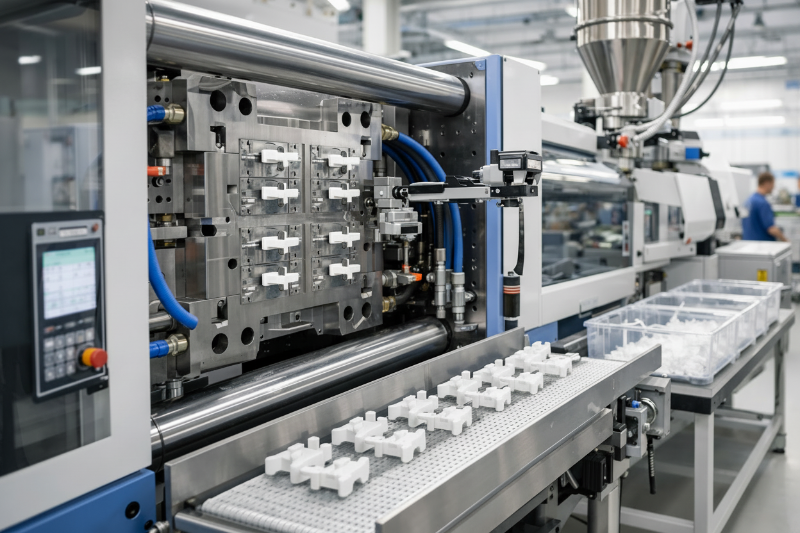

High cavity count for packaging solutions. Focus on tightness, hinge function (flip-top), and cycle time.

- Material: PP / PE

- High-Volume Production

We don't just manufacture parts; we solve requirements. Here you see examples from packaging, technical industry, and assembly. Focus: Process-reliable implementation of your CAD data.

The examples are kept generic. For inquiries, we can coordinate details such as material, tolerances, surfaces, and quantities.

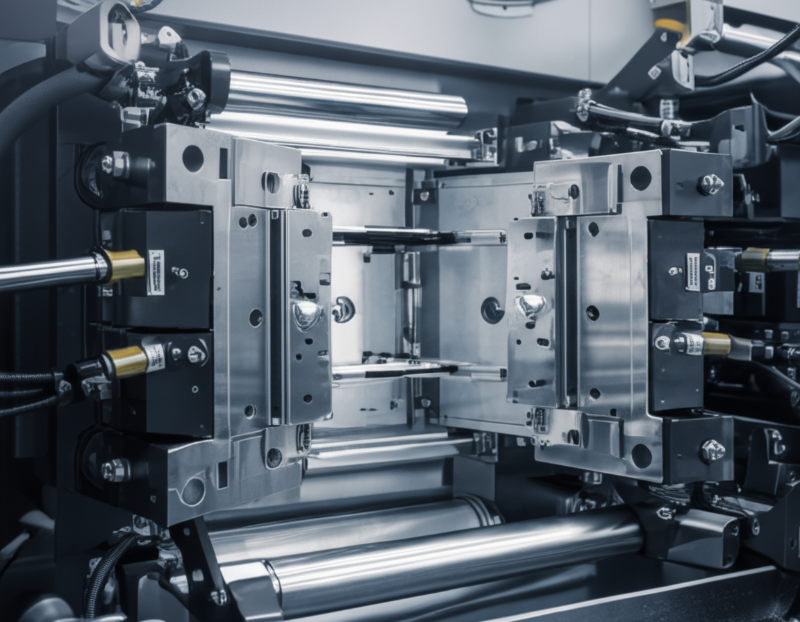

Functional parts, clips, holders, technical housings – Focus on dimensional accuracy and repeatability.

Visible parts and functional components with clean surfaces and clear details.

Customer-specific geometries, snap-fits, hinges – according to specification and use case.

Visualization of typical component requirements.

High cavity count for packaging solutions. Focus on tightness, hinge function (flip-top), and cycle time.

Complex geometry with screw bosses, ribs, and insert nuts. Warpage-free manufacturing for electronic components.

Mechanically resilient parts like clips, holders, and connectors. Designed for tensile strength and elasticity.

Components for the end customer. Flawless surfaces (high gloss or EDM texture) without sink marks.

Value added through assembly. We not only mold, we mount seals, join parts, and pack sets.

Combination of hard and soft components or overmolding of inserts for specific requirements.

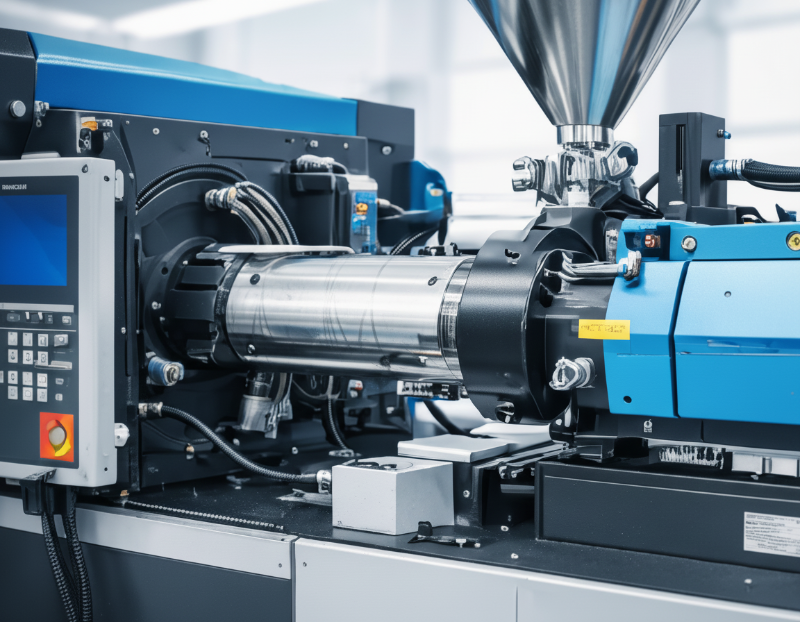

Send us a drawing or a 3D model (STEP/IGES). We check feasibility and material usage and create an offer at short notice.

Request Quote